Drafting Work

After building cabinets and custom millwork for a cabinet manufacturer in Norther Colorado I soon moved into the office and have drafted for them for over 6 years. In that time I have generated production drawings for the shop and installation documentation for installation teams onsite. I have also created custom products not standard to the company's catalog. Below is a sample of my work.

Custom Silverware Insert

Since our local drawer vendor did not supply a silverware insert that matched the customer's expectations I custom engineered a divider system that we would could build in house.

Instructional Documents

To help the drafting team develop a standardized way of creating custom cabinetry to fit specific oven/microwave models I created documentation that supported a wide variety of Manufacturers. Below are two samples.

Drying Rack

Engineered a drying rack solution that accommodates clothing of all sizes. It can be pulled out when needed and stowed when finished and it perfectly integrates with the surrounding cabinetry.

Custom Handle on Panel Doors

Instead of metal hardware customer wanted a custom profiled wood handle that stretched across entire length of cabinets.

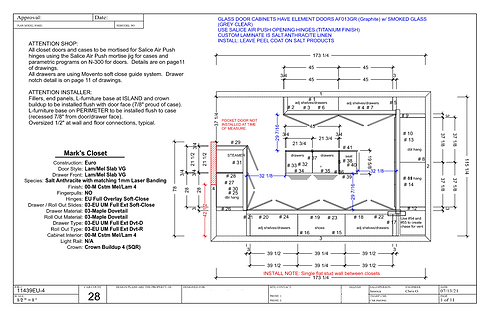

Created Closet Catalog

Collaborated with systems engineer to create a catalog containing parametric cabinets, tops and casework to be used as standard throughout company.

Wood Gola Channel Cabinet

Created a cabinet with gola channel made from wood rather than traditional metal.

Speakeasy Bookcase Door

No explanation needed here right?

Hidden Pantry Door

Customer wanted a hidden pantry behind their cabinets. I engineered a custom jamb and door assembly that integrated with the new cabinetry.

Custom Shiplap Hood with Removable Panel

Customer wanted a built-in hood with a horizontal panel design on three sides. However, hood liner specs required the front panel to be removable. I engineered a three-sided paneled hood with a removable front panel.

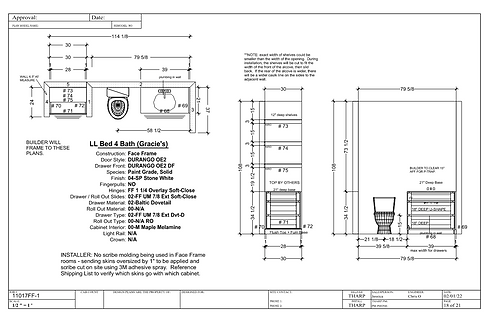

Murphy Bed

Custom Closet with Inset Hinges and Lighting

Custom closet contained hinges that recessed into the case rather than protruding into opening. In addition lighting ran throughout cabinetry. Created custom programs for CNC were created to route hinging into panels.

Created Shelf Build Instructions

Created parametric v-fold shelf and assembly detail for production

Custom Hood with Vertical Slats

Created hood with solid wood slats on three sides. Generated CNC programming to route slots into solid stock for a more efficient and clean looking build.